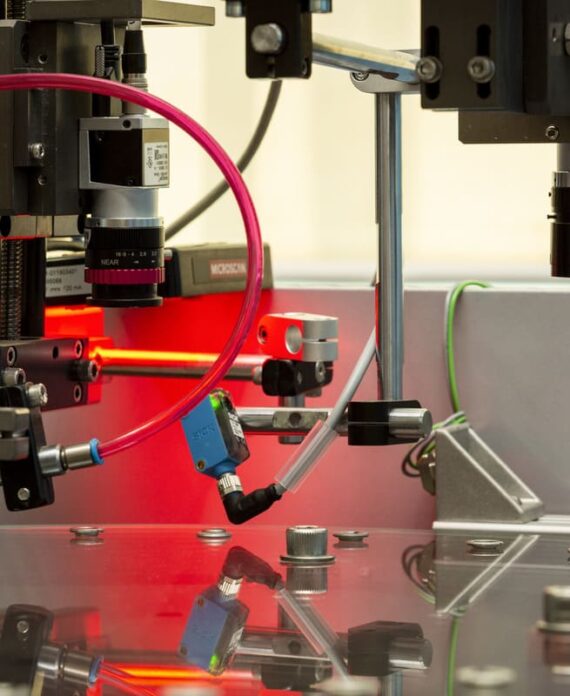

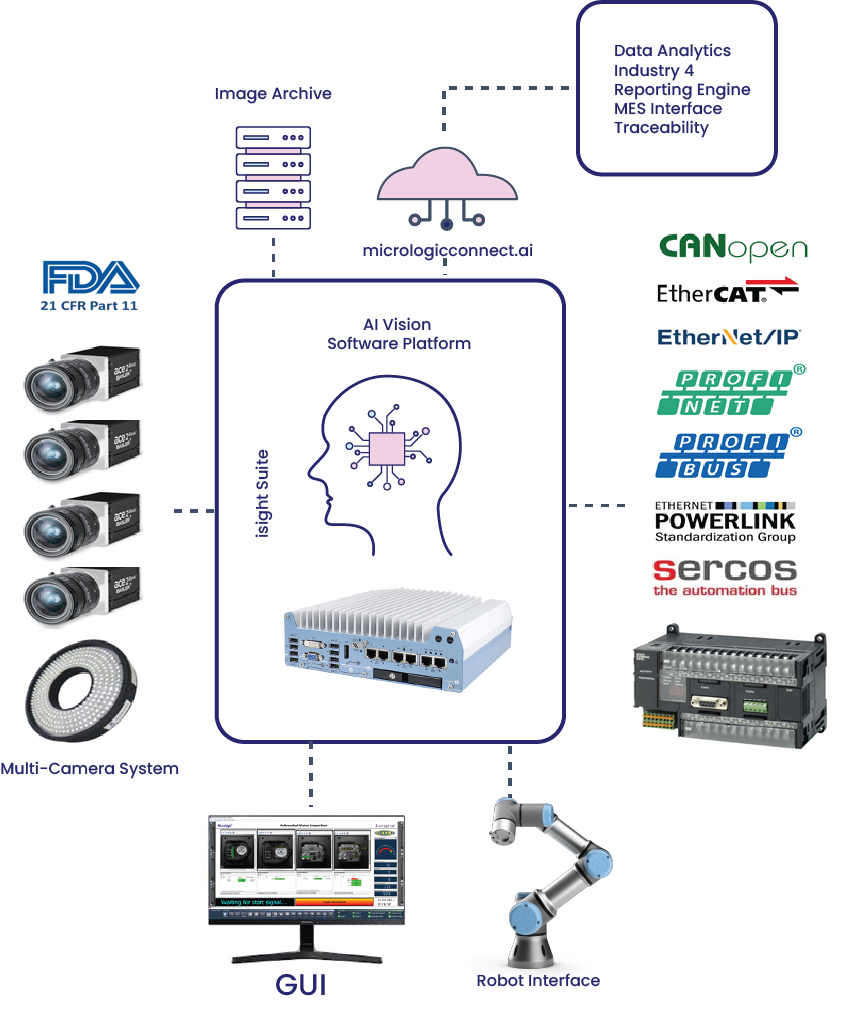

Automated Inspection employs machine vision technology to enable industrial equipment to “see” what it is doing and making rapid decisions based on what is sees. The most common applications of Machine vision are to visually inspect, identify defects, measure dimensions, sorting of parts and reading codes and characters. Machine vision uses cameras, optics, lights, hardware and software in different combinations to acquire and prepare information for use in different applications.

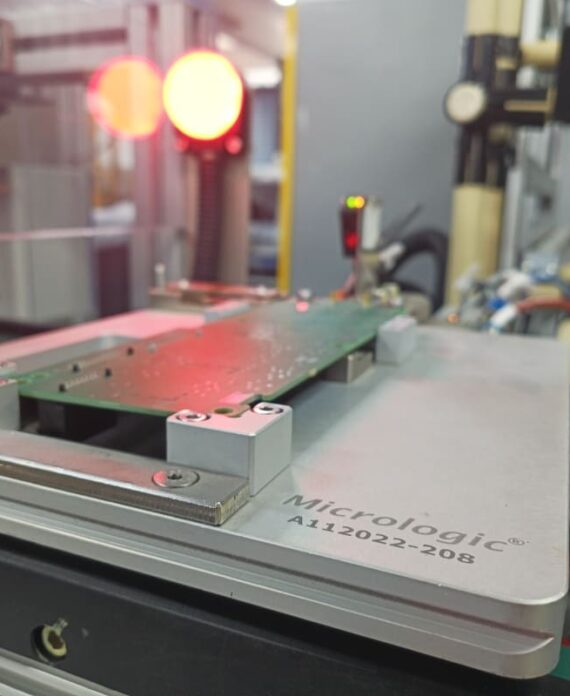

Micrologic isight is a PC based vision platform which is highly scalable.

AI Machine Vision

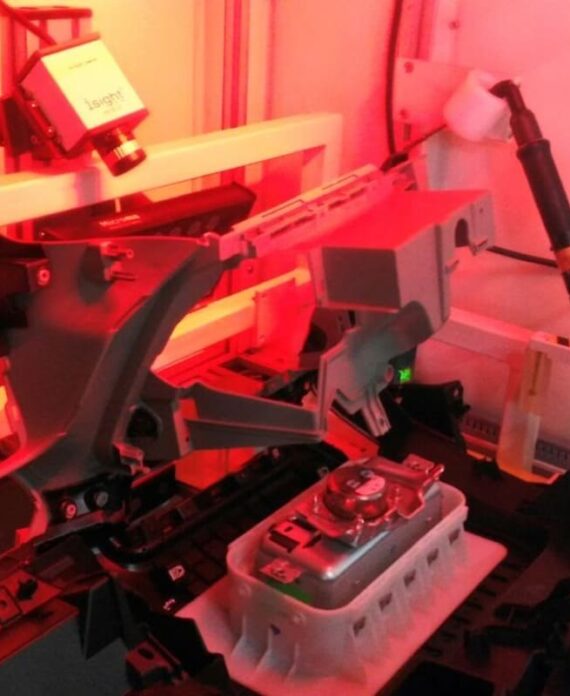

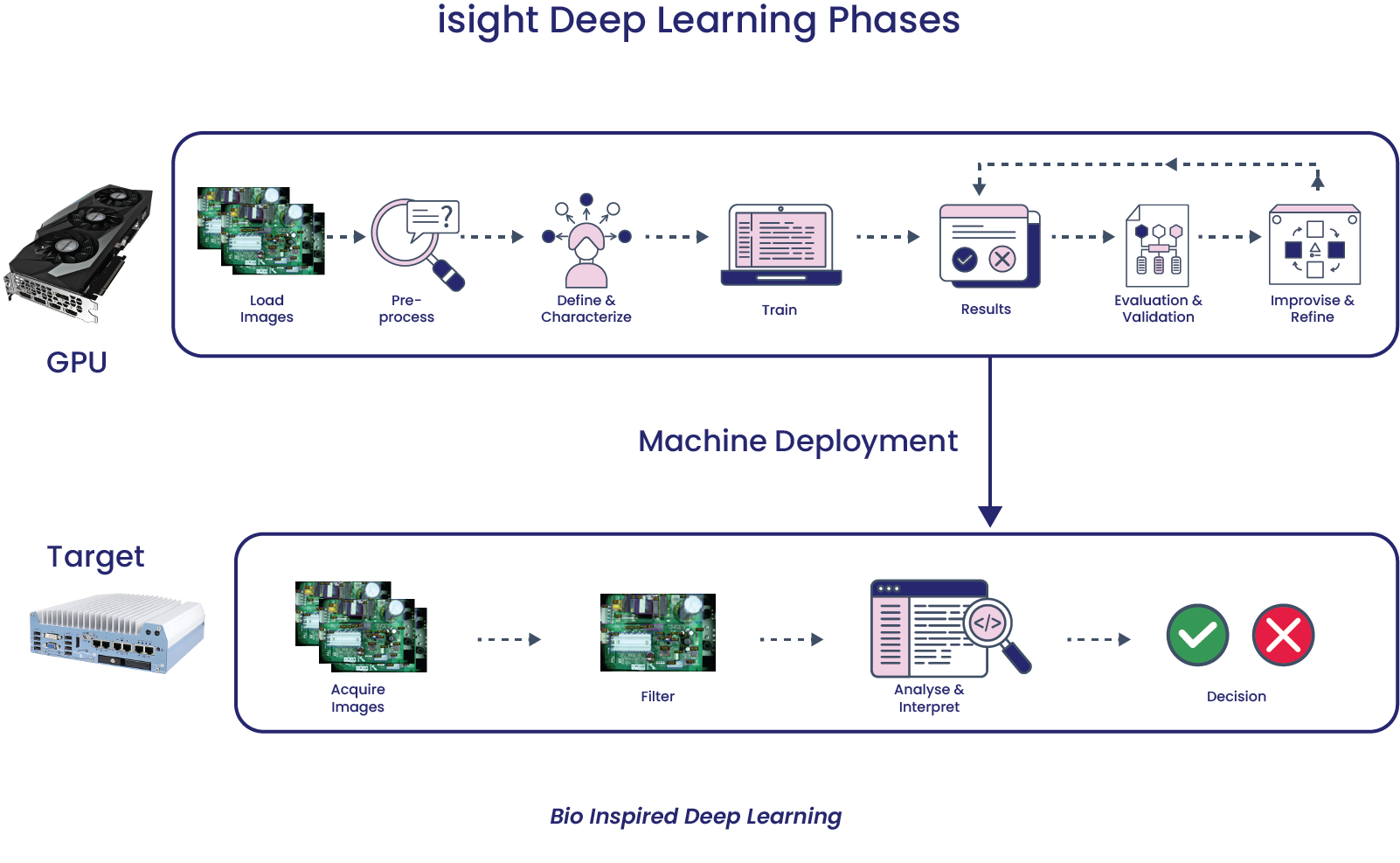

Micrologic isight is an AI Vision platform, the core being an AI Vision software suite running on a powerful computer connected to single or multiple cameras. isight employs Artificial Intelligence (AI) algorithms to see and analyse tasks in manufacturing and quality control.

Artificial intelligence is expanding machine vision far beyond visual inspection and quality control. With smart machine vision, robots can perceive in three dimensions, hold parts for one another, and check each other’s work. They can even interact with human coworkers and make sure they work together safely. isight utilise the deep leaning neural network to learn a task thus allowing the vision system to analyse the images, perceive trends and recognise subtle differences in the images that represent defects and make intelligent decisions on its own.

isight Application

- Presence Verification

- Assembly Integrity

- LED Inspection

- Print Verification

- OCR & OCV

- Direct Part Mark Reading

- Gauging & Dimensional Measurement

- Surface Defect Inspection

- Colour & Intensity Inspection

- Barcode, QR Code, Data Matrix reading

- Robot Guidance

- Deep Learning / AI

- Pattern Recognition / Matching

- Image Archiving

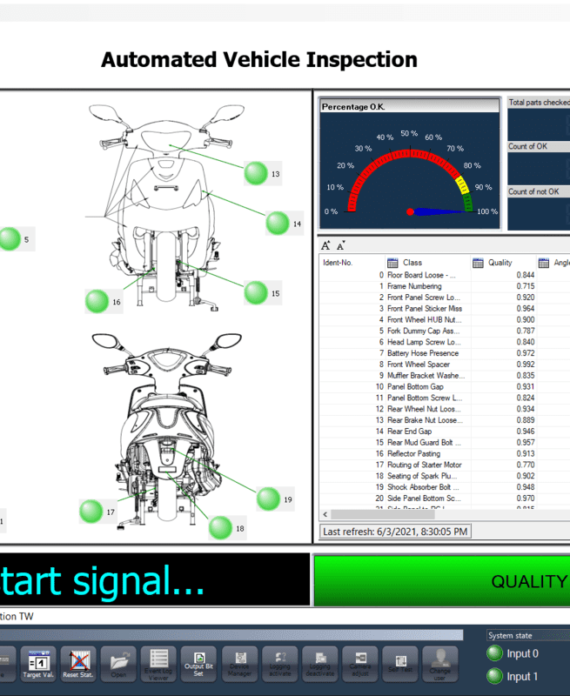

Automotive

- Car Door Panel Assembly Integrity Inspection

- Car Roof Panel Assembly Integrity Inspection

- Engine Casting Machining Inspection

- Surface Defect Inspection of precision parts

- Full Vehicle PDI Inspection

- Vehicle End of Line Part traceability

- Optical Sorting Machine

- Sub assembly Inspection

- Direct Part Mark Reading on engine casting

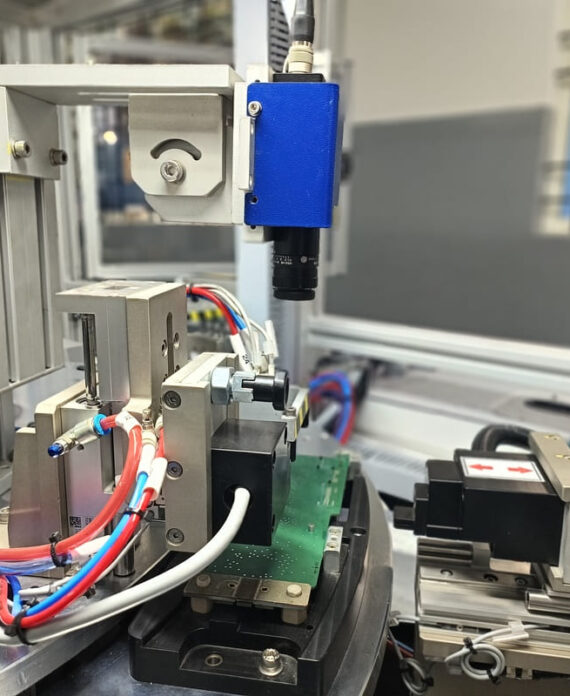

Electronics

- PCBA Soldering Inspection

Medical

- Surgical Glove Inspection

Others

- Print Quality Inspection